Diagnostic

Diagnostic

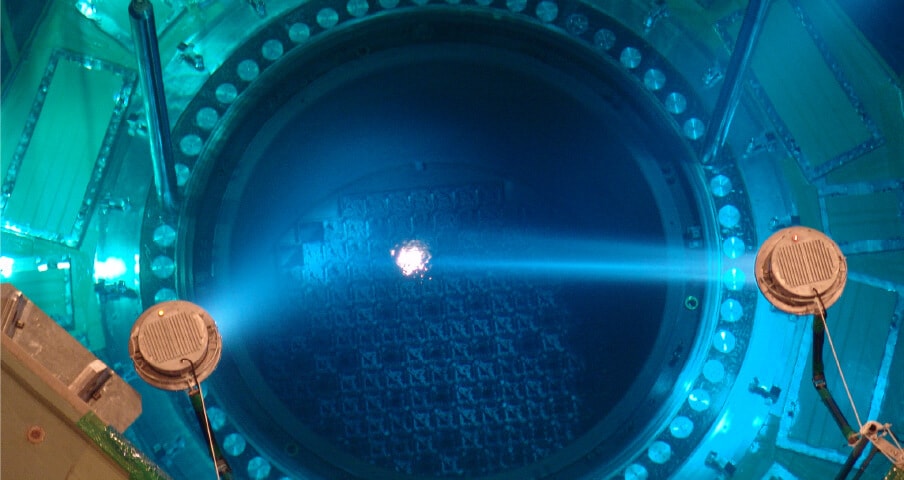

Inspection of Steam Generator Tubes

Using eddy current testing (ECT), abnormalities in steam generator heat transfer tubes are detected to prevent serious accidents from occurring.

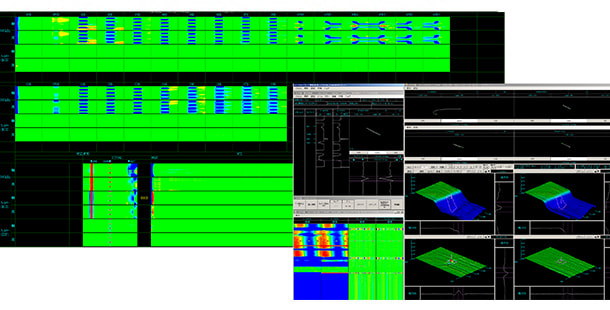

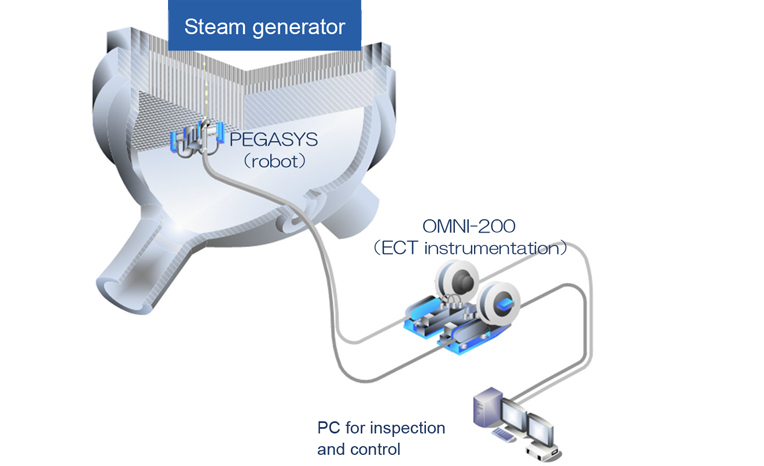

One of the Plant Diagnostic Group tasks is to evaluate the integrity of the heat transfer tubes inside the steam generator, which is the important equipment in a nuclear power plant. Employed inspection method is eddy current testing (ECT), in which a sensor (probe) equipped with coils is inserted into the heat transfer tube to be inspected, and a high-frequency current is applied to check for flaws in the tube wall. The data acquired during the inspection is analyzed with a high degree of accuracy.

Currently, we have introduced the latest eddy current instrumentation (OMNI-200) and robot (PEGASYS) to greatly improve efficiency, and have also developed the next-generation Smart Array ECT system in-house to further improve accuracy.

Smart array ECT system

Schematic drawing of SG tube inspection system

Diagnostic

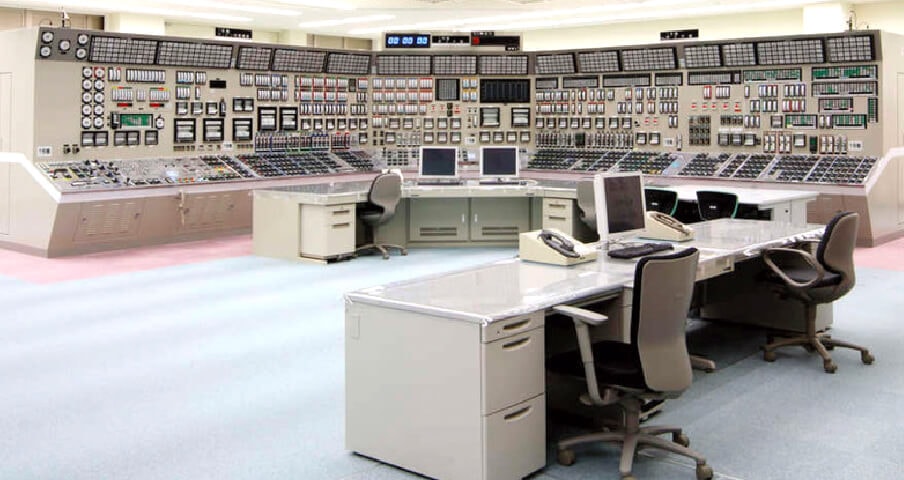

Piping Weld Inspection

Nondestructive examination using ultrasonic testing is performed to confirm the integrity of nuclear power plant equipment.

Ultrasonic inspection methods are widely used for nondestructive testing to confirm the integrity of reactor vessels and piping.

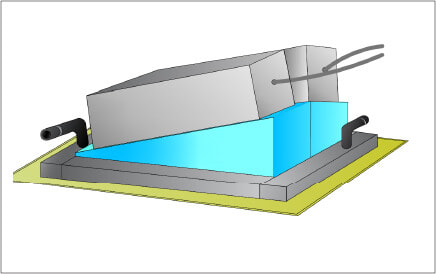

In recent years, as the age of plants has increased, it has become necessary to further improve inspection performance and to inspect areas that were not previously required. We have been studying a new ultrasonic inspection technology for the primary system piping made of cast stainless steel, which has been considered difficult to be inspected with ultrasonic testing. By using a large size low-frequency probe newly developed through this study, it is possible to perform inspections with higher reliability than before, thereby improving the reliability of plants.

Large size probe

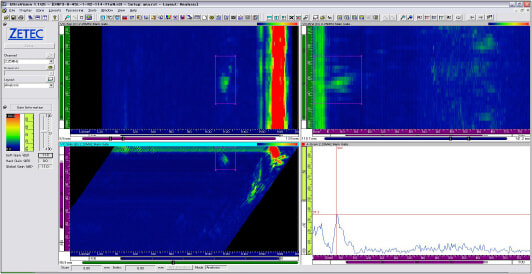

Example of UT indications

Diagnostic

Piping Vibration Measurement

In order to prevent the fatigue failure at small bore connection (SBC) in piping, we measure two directional bending stains and one pipe-axial torsional stain synchronously and calculate each stress and the combined stress of them in real fields.The measurement of the multiaxial stress in real fields can be realized by the “Strain Gauge Holder” we have developed. This Strain Gauge Holder has four strain gauge rosettes, which means twelve elements of strain gauge and can perform the strain measurement at 230℃ SBC. The installation time in real fields is usually less than 20 minutes.From the measured data, we calculate the fatigue damage value at each circumferential location of the SBC and lead the critical fatigue life prediction.

If you are interested in the detail of our assessment of piping vibration, please do not hesitate to contact us.

Strain Gauge Holder

Measurement example of multiaxial stress by four strain gauge rosettes(Two bending stresses σx and σy, and one torsional stress τz)

Calculation Example of critical fatigue life prediction

Diagnostic

Radiation Measurement

Our advanced radiation measurement technology contributes to the analysis of radionuclides in nuclear power plant reactor water and the evaluation of radiation work environments.

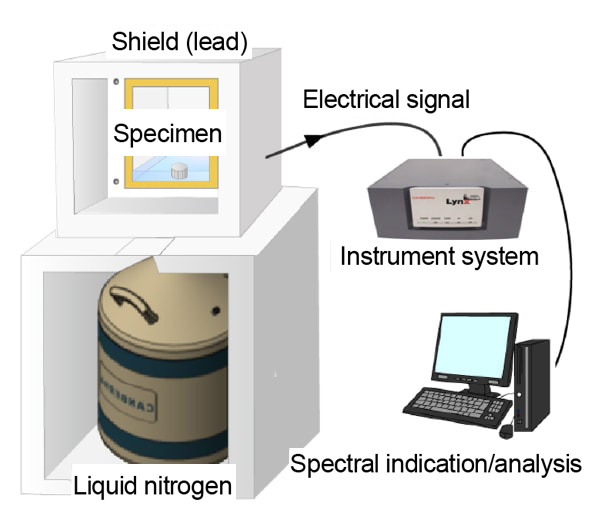

In nuclear power plants, it is necessary to properly analyze and control radionuclides contained in the reactor water and radioactive waste. We have delivered a germanium (Ge) pulse height analyzer to Kansai Electric Power Company, which is able to analyze gamma-ray emitting radionuclides, and perform annual inspection and maintenance of the system. The analysis data obtained is transferred to the waste management system that we have developed, contributing to the stable operation of the nuclear power plant.

Radioactive nuclides, such as cobalt, are deposited inside the primary system component and piping of nuclear power plants, and these nuclides become a source of radiation exposure for workers during periodic inspections. We follow the deposition of radionuclides over time using high performance CZT (Cadmium Zinc Telluride) detectors, etc., and contribute to the evaluation of the radiation work environment at each periodic inspection.

Ge pulse height analyzer

CZT (Cadmium Zinc Telluride) detector

Diagnostic

Maintenance of SG Secondary Side

In order to maintain the integrity and performance of steam generators, evaluation and cleaning are carried out using the advanced technology.

Many of the steam generator problems are caused by the deposition of corrosion products (mostly iron oxides = scale) that are contained in the feedwater, and the monitoring and control of scale deposit is the key for steam generator secondary side maintenance. In addition to quantitatively assessing the scale deposit, we are studying water chemistry c methods to control the inflow of corrosion products and advanced cleaning methods to remove the deposited scale.

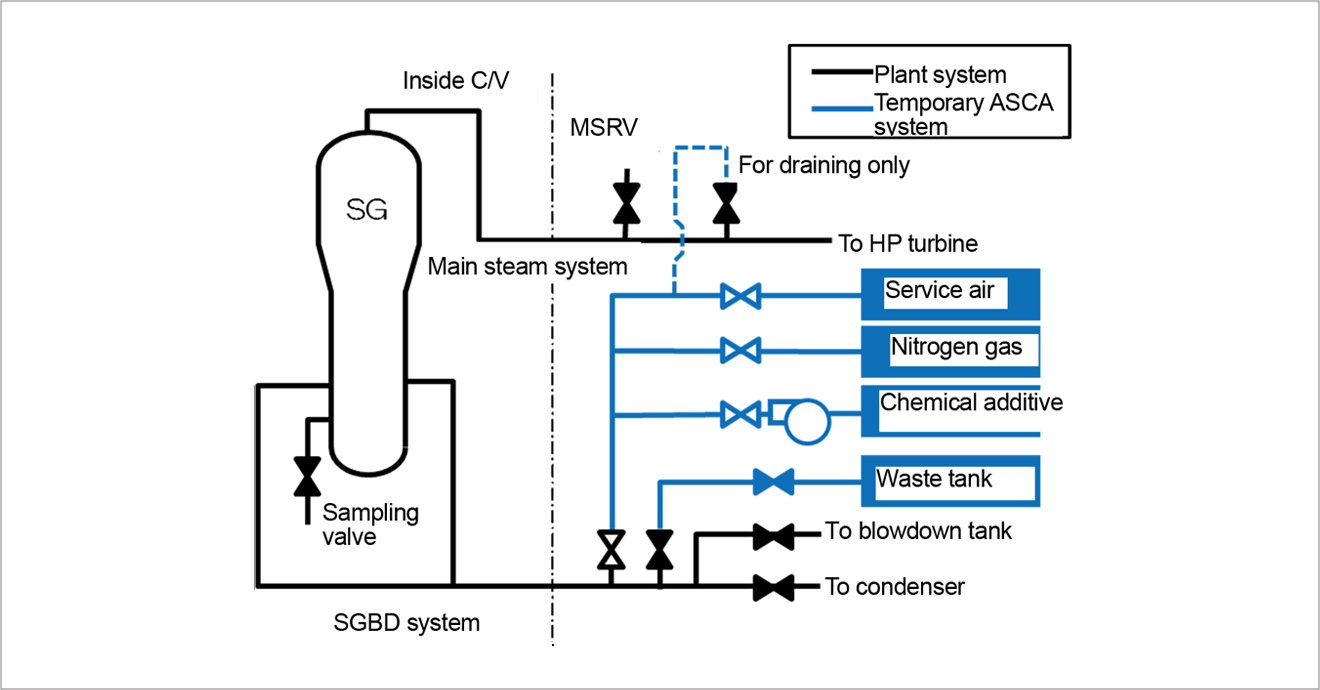

For the quantitative evaluation of scale deposit, we have developed a subtraction method to extract only the scale indications from the tube support plate indications obtained by eddy current flaw detection. An evaluation curve is created from the measured blockage ratio obtained from visual inspection results, and the blockage ratio of the tube support plate due to scale deposit is calculated using this curve. The blockage ratio of the tube support plate is used to determine when cleaning will be necessary in the future.The cleaning method we use is called ASCA (Advanced Scale Conditioning Agent), which is a type of chemical cleaning. When the plant is shut down, we use chemical additives to make the heat transfer tube scale on the secondary side of the steam generator porous, thereby restoring the heat transfer performance of the steam generator and improving the blockage of the tube support plate.

Schematic diagram of ASCA application