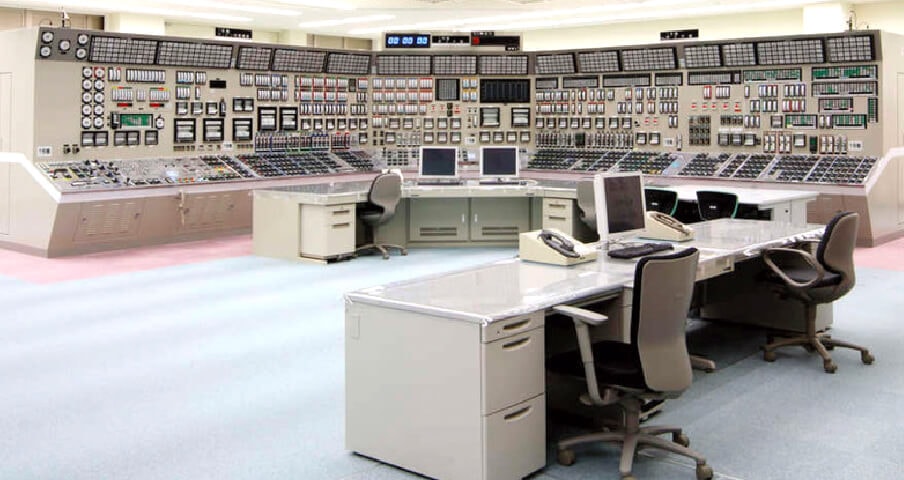

Maintenance

Maintenance

Advanced Maintenance Technology

We contribute to improving the safety and reliability of nuclear power plant facilities.

“Advanced maintenance" aims to study and realize more effective and efficient methods of performing maintenance activities (inspections and other activities to ensure that equipment operates reliably at all times) on various equipment such as pumps, valves, and motors that are necessary for the operation of nuclear power plants. We work together with our customers to solve problems by providing comprehensive engineering services, including the collection and analysis of data obtained from daily maintenance activities, the enhancement of databases for managing information, and the formulation of optimal maintenance plans based on technical knowledge. We also keep our eyes open for good practices overseas, and are working to further improve maintenance activities at nuclear power plants in Japan.

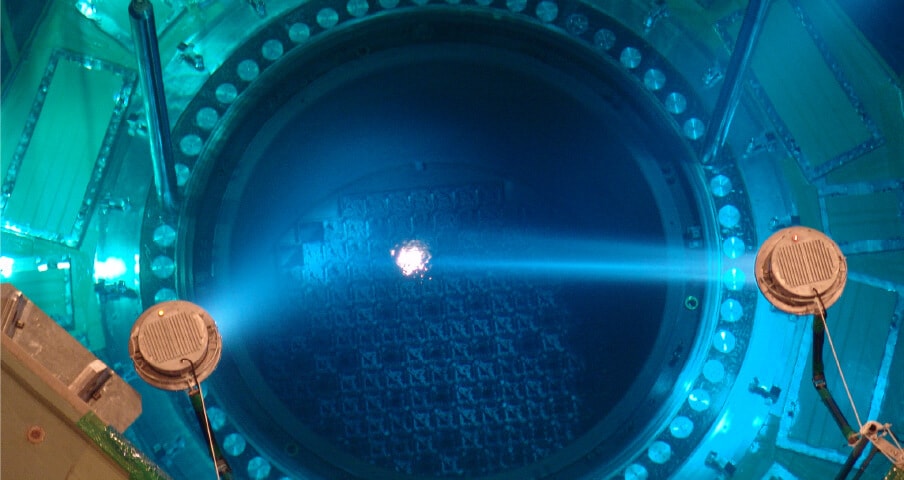

Maintenance

Tough Joint Technology

We contribute to the preventive maintenance against ageing degradation and damage of nuclear power plant facilities developing over time.

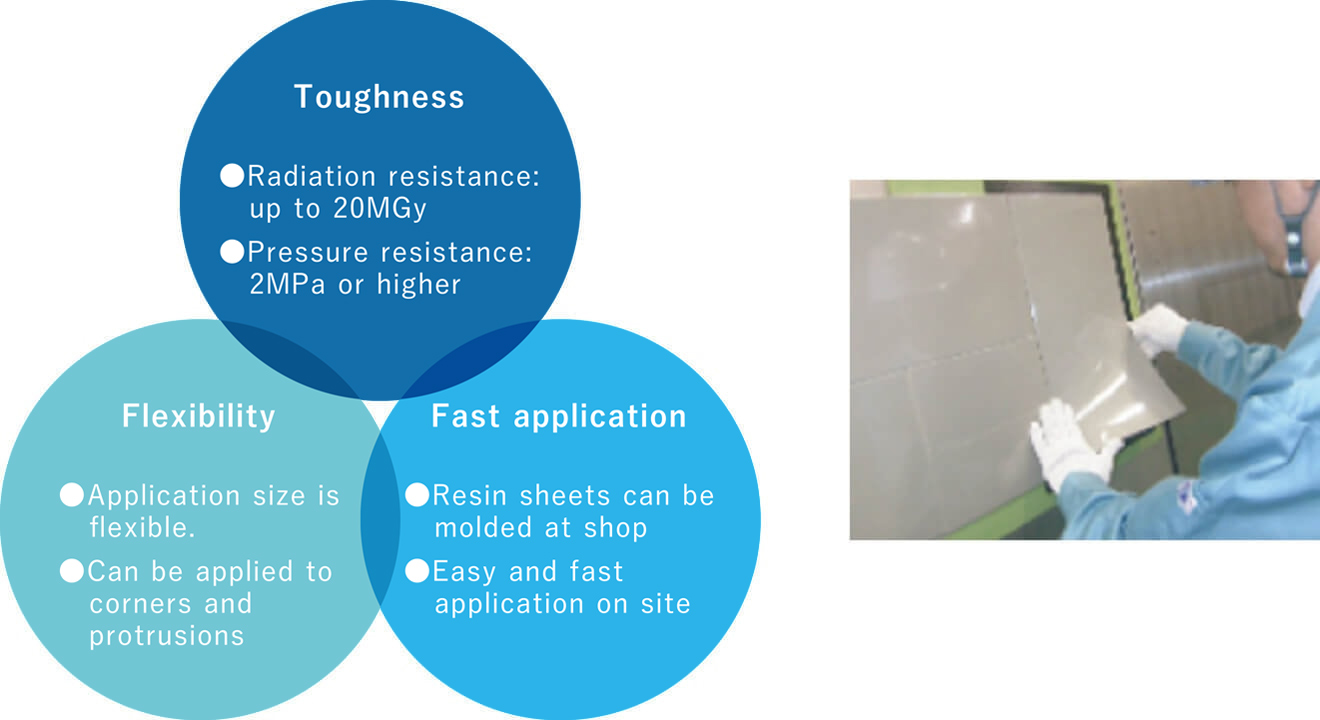

The "Tough Joint" is a radiation-resistant resin sheet and its application technology developed in-house for preventive maintenance against water leakage from tanks and pools in nuclear power plants. We have applied “Tough Joint” at many plants with a one-touch process that allows easy repair of the sheet, and has been certified and patented by the Japan Power Engineering and Inspection Corporation (Patent No. 4308880). Since the width and length of the resin sheet can be freely designed, it can be applied to any shape, even around corners, curved surfaces, and protrusions, to meet the diverse needs of customers. In addition, compared to conventional repair work (re-welding), the time required for on-site work can be greatly reduced, which makes Tough Joint attractive for low-cost application.

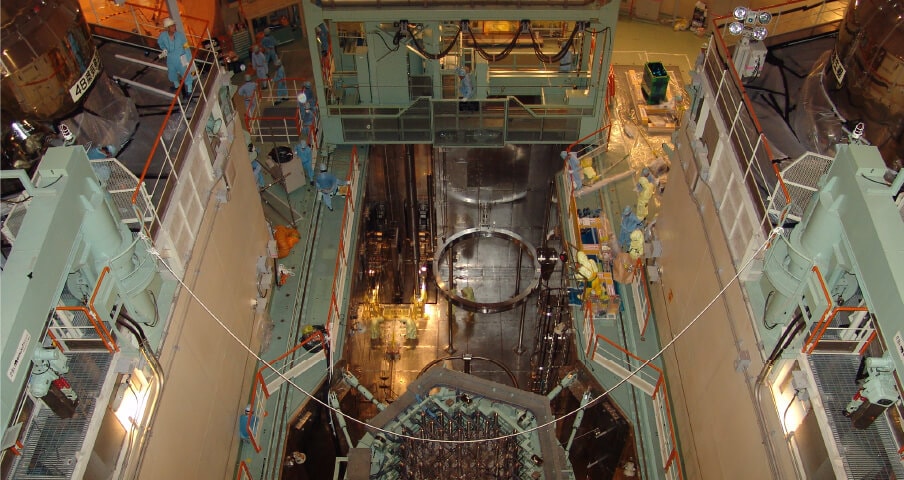

Maintenance

Support for Legal Compliance

We give support to the plant operator for the prevention of omission of legal procedures that must be complied with in operating a nuclear power plant.

In addition to general laws, such as the Fire Service Act and the Industrial Safety and Health Act, operating a nuclear power plant requires compliance with laws specific to nuclear power plants (Nuclear Reactor Regulation Law, Electricity Business Act, etc.). The number of amendments to these laws and regulations exceeds 10,000 per year, and in order to prevent omissions in the procedures t legal amendments, it is necessary to ensure that information on legal amendments can be reliably obtained.

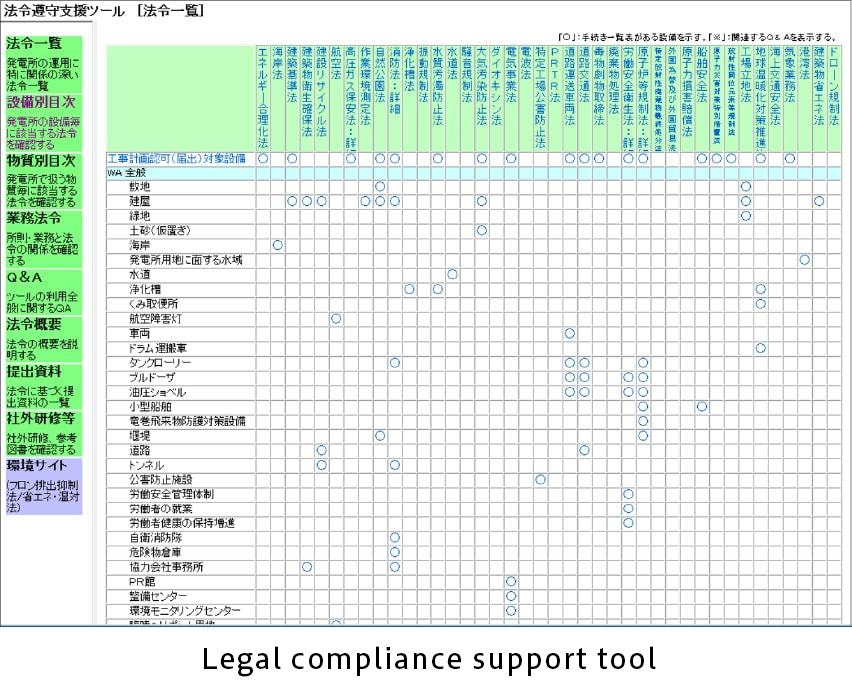

Under the contract with Kansai Electric Power Company, we monitor and review information on revisions to the laws and regulations on a daily basis, not only for important nuclear laws such as the Nuclear Reactor Regulation Law and the Electricity Business Law, but also for general laws such as the Fire Service Law and the Industrial Safety and Health Law, and not only for official journals but also for prefectural gazettes, in light of the equipment and materials used in nuclear power plants, and the results are distributed in a timely manner. In addition, we have developed a "legal compliance support tool" to confirm that there are no problems in the application procedures required by each law, and the tool is currently being utilized by Kansai Electric Power Company.

We also provide support to Chugoku Electric Power Company based on the versatility of our work and our accumulated technical capabilities in providing support for legal compliance.

Maintenance

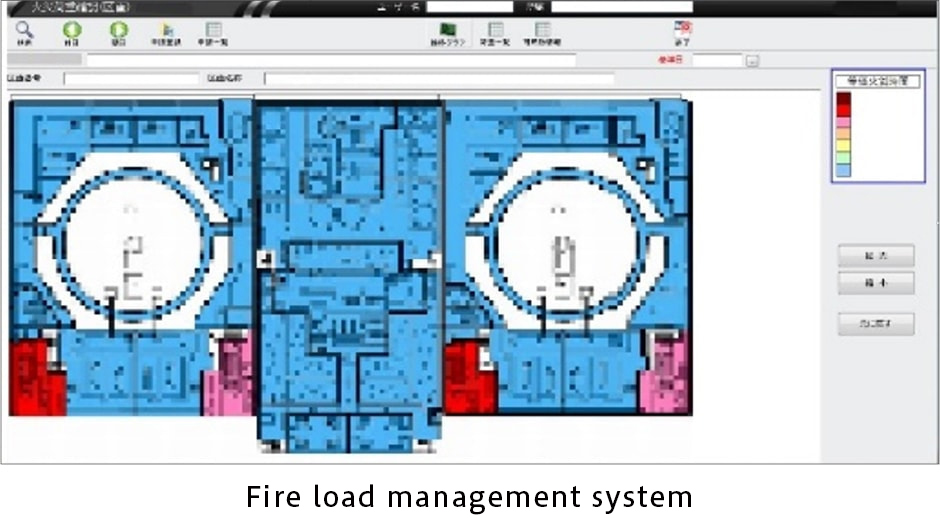

Evaluation of Effects of Internal Fire

We contribute to maintaining the safety of power plants by supporting the evaluation and operation management of fire protection measures.

Fire protection measures at nuclear power plants (measures to protect nuclear power plants from fire) were first introduced following the fire at Kashiwazaki-Kariwa Nuclear Power Station caused by the Chuetsu-Oki Earthquake in 2007. The fore protection measures were further strengthened in the new regulatory requirements established in response to the accident at Fukushima Daiichi Nuclear Power Station. A fire in a power plant building can have a significant impact on the safety of the reactor.

The evaluation of the effects of internal fire determines the impact of a fire on the equipment to be protected and the validity of the countermeasures.

Under the contracts with Kansai Electric Power Company, Hokkaido Electric Power Company, Chugoku Electric Power Company, Tohoku Electric Power Company and others, we perform the following tasks;

・Confirming the effects of a fire on the equipment required to safely shut down the reactor

(analysis and data of fire propagation)

・Confirmation (based on ten results of fire propagation analysis and data analysis)

・Investigation of the layout of safety-related equipment and preparation of various layout drawings

・Survey of combustible materials, evaluation of fire load (fire duration based on calorific values)

・Support for the development and operation of fire load management system

・Support for the establishment of a comprehensive maintenance and management system of fire protection measures